A company has an inventory of 1250 assorted parts, each one meticulously organized and accounted for. From nuts and bolts to complex machinery, this vast collection of components forms the backbone of the company’s operations, ensuring smooth production and efficient delivery.

Managing such a diverse inventory requires a symphony of strategies and techniques. Effective inventory management techniques optimize stock levels, minimizing waste and carrying costs. Inventory valuation methods, such as FIFO, LIFO, and weighted average, provide accurate financial reporting. And inventory optimization strategies, like improving inventory turnover and reducing lead times, keep the supply chain humming.

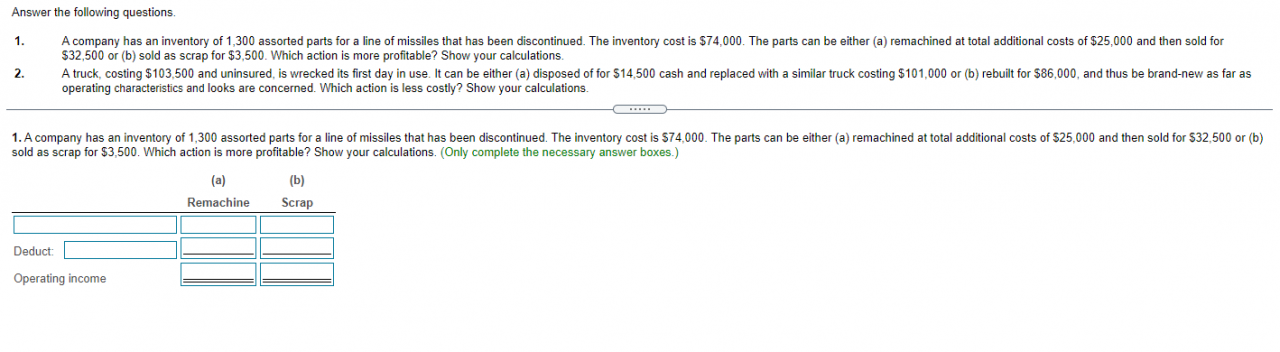

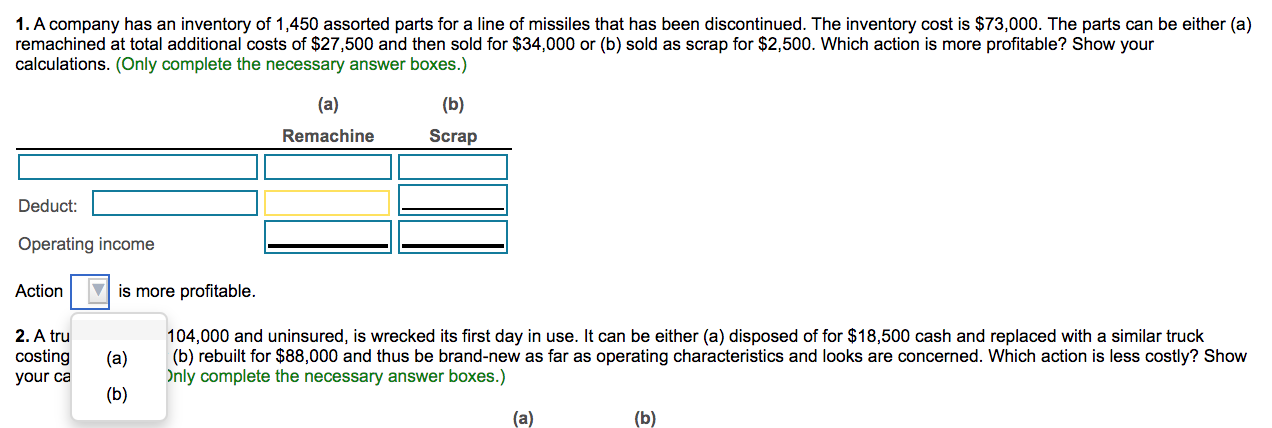

Inventory Valuation Methods

Inventory valuation methods are accounting techniques used to determine the value of a company’s inventory. Choosing the right method can significantly impact financial statements and tax implications. The most common inventory valuation methods are FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and Weighted Average Cost.

FIFO (First-In, First-Out)

Under FIFO, the cost of goods sold is based on the assumption that the oldest inventory is sold first. This means that the cost of goods sold is calculated using the cost of the earliest purchases. FIFO can result in higher cost of goods sold and lower net income during periods of rising prices.

A company has an inventory of 1250 assorted parts, which is a lot to keep track of. Speaking of keeping track of things, have you ever wondered can a ipad text an android ? It’s a valid question, especially if you have friends or family who use different types of phones.

Back to the inventory, 1250 parts is a lot to manage, but with the right inventory system, it can be done efficiently.

LIFO (Last-In, First-Out)

LIFO assumes that the most recently purchased inventory is sold first. This can result in lower cost of goods sold and higher net income during periods of rising prices. However, LIFO can also lead to lower inventory values and higher taxes during periods of falling prices.

Weighted Average Cost

Weighted average cost assigns an average cost to all units of inventory. This method is less sensitive to price fluctuations than FIFO or LIFO and can result in a more stable cost of goods sold. However, weighted average cost can be more complex to calculate than FIFO or LIFO.

Selecting the Most Appropriate Method

The choice of inventory valuation method depends on several factors, including the nature of the business, the industry, and tax implications. FIFO is often used by companies with rapidly changing inventory, while LIFO is more common in industries with stable or declining prices.

Weighted average cost is a good option for companies with a diverse inventory or those that want to smooth out the impact of price fluctuations.

Inventory Optimization

Inventory optimization is a crucial aspect of supply chain management, aiming to maintain optimal inventory levels while minimizing costs and maximizing customer satisfaction. One key metric used to assess inventory performance is the inventory turnover ratio.The inventory turnover ratio measures how efficiently a company is using its inventory.

It is calculated by dividing the cost of goods sold (COGS) by the average inventory value. A higher inventory turnover ratio indicates that the company is selling its inventory quickly and efficiently, while a lower ratio suggests that the company is holding onto inventory for too long.Improving

A company has an inventory of 1250 assorted parts, including circuit boards, wires, and other components. These parts can be used to assemble a variety of products, including computers, phones, and other electronic devices. If you’re wondering can an android phone be tracked , the answer is yes.

Most Android phones have a built-in GPS chip that allows them to be tracked by their owners or by law enforcement. This can be useful if your phone is lost or stolen, but it can also be a privacy concern.

If you’re concerned about your privacy, you can disable the GPS chip in your phone’s settings.

inventory turnover can lead to significant benefits for a company. It can reduce inventory carrying costs, such as storage, insurance, and handling expenses. It can also free up cash flow that can be used for other purposes, such as investing in new products or expanding operations.There

are several strategies that companies can use to improve inventory turnover and reduce lead times. These include:

-

-*Using just-in-time (JIT) inventory management

JIT is a production strategy that aims to minimize inventory by producing products only when they are needed. This can help to reduce inventory carrying costs and lead times.

-*Implementing vendor-managed inventory (VMI)

VMI is a partnership between a company and its suppliers in which the supplier manages the company’s inventory. This can help to improve inventory visibility and reduce lead times.

-*Using technology to optimize inventory levels and forecast demand

Technology can be used to track inventory levels in real time and forecast demand. This information can be used to make informed decisions about inventory levels and avoid overstocking or understocking.

By implementing these strategies, companies can improve inventory turnover and reduce lead times, which can lead to significant cost savings and improved customer satisfaction.

With a company having an inventory of 1250 assorted parts, it’s like having a treasure trove of possibilities. Just like how the question of whether an iPhone can video chat with an Android phone sparks curiosity, the diverse inventory opens up a world of potential combinations and solutions.

It’s like a puzzle where each part represents a piece of the solution, waiting to be assembled into something extraordinary.

Inventory Replenishment

Inventory replenishment is the process of determining when and how much inventory to order to maintain optimal stock levels. There are several inventory replenishment strategies, each with its own advantages and disadvantages.

Just-in-Time (JIT)

JIT is an inventory replenishment strategy that aims to minimize inventory levels by ordering only what is needed, when it is needed. This strategy is based on the assumption that demand is relatively stable and predictable, and that suppliers can deliver goods quickly and reliably.

- Advantages:Reduces inventory carrying costs, improves cash flow, and frees up storage space.

- Disadvantages:Requires close coordination with suppliers, can lead to stockouts if demand is not accurately forecasted, and may result in higher shipping costs.

Economic Order Quantity (EOQ)

EOQ is an inventory replenishment strategy that aims to minimize the total cost of inventory, including ordering costs and carrying costs. The EOQ formula takes into account the following factors:

EOQ = √(2*D*O)/H

- D = annual demand for the item

- O = ordering cost per order

- H = carrying cost per unit per year

Advantages:Minimizes total inventory costs, reduces the risk of stockouts, and is relatively easy to implement.

A company has an inventory of 1250 assorted parts. These parts are used to assemble a variety of products, including electronics, appliances, and furniture. If you’re wondering can i track an android phone from an iphone , the answer is yes.

There are a number of apps that allow you to do this. Once you’ve installed the app, you can simply enter the phone number of the Android phone you want to track. The app will then provide you with the location of the phone in real time.

This can be a helpful way to keep track of your children or employees, or to find a lost or stolen phone.

Disadvantages:Assumes that demand is constant, may not be suitable for items with high demand variability, and can lead to higher inventory levels than JIT.

A company has an inventory of 1250 assorted parts. But if you’re more of an Android fan, you might be wondering: can i use apple carplay with an android phone ? The answer is yes, but you’ll need an adapter.

Adapters are relatively inexpensive and easy to find online or at your local electronics store. Once you have an adapter, you can connect your Android phone to your car’s infotainment system and enjoy all the benefits of Apple CarPlay, including hands-free calling, texting, navigation, and music streaming.

A company has an inventory of 1250 assorted parts, so you’re sure to find the right one for your needs.

Selecting the Most Suitable Replenishment Strategy

The choice of inventory replenishment strategy depends on a number of factors, including:

- Demand patterns

- Supplier reliability

- Inventory carrying costs

- Ordering costs

- Business model

For example, JIT is often used in manufacturing environments where demand is relatively stable and suppliers can deliver goods quickly. EOQ is often used in retail environments where demand is more variable and inventory carrying costs are higher.

Inventory Control

Inventory control is crucial for businesses to prevent theft, loss, and damage, ensuring the accuracy and efficiency of inventory management.

Effective inventory control techniques include:

Cycle Counting, A company has an inventory of 1250 assorted parts

- Regularly counting and reconciling inventory at specific intervals to identify discrepancies and prevent shrinkage.

- Helps detect errors in inventory records and prevent theft or loss.

Perpetual Inventory Systems

- Real-time tracking of inventory levels through software or manual updates after each transaction.

- Provides up-to-date information on inventory availability, reducing the risk of overstocking or stockouts.

Best Practices for Effective Inventory Control

- Establish clear inventory policies and procedures.

- Implement regular inventory audits and reconciliations.

- Use technology to automate inventory tracking and monitoring.

- Train staff on inventory management best practices.

- Implement security measures to prevent theft and unauthorized access.

Inventory Forecasting

Inventory forecasting is the process of predicting future demand for inventory items. It is a critical part of inventory management, as it helps businesses to ensure that they have the right amount of inventory on hand to meet customer demand.

There are a number of different methods that can be used to forecast inventory demand, and the best method for a particular business will depend on a number of factors, such as the industry, the product, and the availability of data.

A company has an inventory of 1250 assorted parts. To keep track of these parts, they’re using the latest technology, including BlueStacks , an Android emulator that’s fast, secure, and easy to use. With BlueStacks, the company can easily manage their inventory, track orders, and stay organized.

This has helped them to improve their efficiency and accuracy, and it’s also saved them time and money. Now, the company can focus on what they do best: providing their customers with the best possible products and services. They’re also using BlueStacks to develop new products and services, and they’re excited to see what the future holds.

Some of the most common inventory forecasting methods include:

- Moving averages

- Exponential smoothing

- Trend analysis

- Seasonal analysis

Moving averages and exponential smoothing are two of the most popular inventory forecasting methods. Moving averages involve taking the average of the demand for a product over a specified period of time. Exponential smoothing involves taking the weighted average of the demand for a product over a specified period of time, with the most recent demand being given the most weight.

Trend analysis and seasonal analysis are two other inventory forecasting methods that can be used to improve the accuracy of forecasts. Trend analysis involves identifying the trend in demand for a product over time. Seasonal analysis involves identifying the seasonal patterns in demand for a product.

Yo, check this out! A company’s got a stash of 1250 parts. But hold up, did you know you can add an Android to Find My iPhone ? That’s right, game-changer! Now, back to that inventory—1250 parts, all waiting to be assembled into something epic.

The best inventory forecasting method for a particular business will depend on a number of factors, such as the industry, the product, and the availability of data. It is important to experiment with different methods to find the one that works best for your business.

Factors that Influence Inventory Demand Forecasting

There are a number of factors that can influence inventory demand forecasting, including:

- Economic conditions

- Industry trends

- Product life cycle

- Marketing and sales promotions

- Customer behavior

It is important to consider all of these factors when forecasting inventory demand. By doing so, you can improve the accuracy of your forecasts and ensure that you have the right amount of inventory on hand to meet customer demand.

Selecting the Most Appropriate Forecasting Method

The best inventory forecasting method for a particular business will depend on a number of factors, such as the industry, the product, and the availability of data. Here are some tips for selecting the most appropriate forecasting method:

- Consider the industry in which your business operates. Some industries are more predictable than others. For example, the demand for food is relatively stable, while the demand for fashion items is more volatile.

- Consider the product that you are forecasting. Some products have a long life cycle, while others have a short life cycle. For example, the demand for a new car is likely to be more stable than the demand for a new fashion item.

- Consider the availability of data. Some businesses have a lot of historical data on demand, while others have very little. The more data you have, the more accurate your forecasts will be.

By considering these factors, you can select the inventory forecasting method that is most appropriate for your business.

Inventory Reporting

Inventory reporting provides valuable insights into the current state and performance of a company’s inventory. It helps businesses track stock levels, identify trends, and make informed decisions about inventory management.Different types of inventory reports serve specific purposes:

Inventory Summary Reports

These reports provide a comprehensive overview of the inventory, including total quantity, value, and key metrics like turnover rate and days on hand. They help businesses assess the overall health of their inventory and identify areas for improvement.

Stock Status Reports

Stock status reports provide real-time information on the availability of specific items. They show current stock levels, reorder points, and expected delivery dates. This data helps businesses prevent stockouts, avoid overstocking, and optimize inventory levels.

Inventory Audits: A Company Has An Inventory Of 1250 Assorted Parts

Inventory audits are essential for businesses to maintain accurate inventory records and ensure compliance with accounting standards. They involve physically counting and verifying the quantities of inventory on hand, comparing them to the records, and investigating any discrepancies.Regular inventory audits help businesses identify errors in inventory records, prevent theft and fraud, and optimize inventory management.

They also provide assurance to stakeholders, such as investors and auditors, that the company’s financial statements are accurate and reliable.

Types of Inventory Audits

There are two main types of inventory audits:

- Physical Audits:Involve counting all the inventory on hand at a specific point in time. They are typically conducted annually or semi-annually.

- Cycle Counts:Involve counting a portion of the inventory on a regular basis, such as monthly or quarterly. They help to identify errors and discrepancies early on, preventing them from becoming larger problems.

Planning and Executing Effective Inventory Audits

Effective inventory audits require careful planning and execution. Businesses should consider the following steps:

- Establish clear objectives:Determine the specific goals of the audit, such as verifying inventory accuracy or detecting theft.

- Choose the right audit method:Select the appropriate type of audit (physical or cycle count) based on the size and complexity of the inventory.

- Train audit team:Ensure that the audit team is properly trained to conduct accurate counts and identify potential errors.

- Prepare the inventory:Organize the inventory in a way that facilitates easy counting, such as by category or location.

- Execute the audit:Conduct the audit according to the planned procedures, ensuring that all items are counted and discrepancies are documented.

- Analyze results and take corrective action:Review the audit results, identify any errors or discrepancies, and implement corrective actions to improve inventory accuracy and management.

Ultimate Conclusion

In the realm of inventory management, this company’s 1250 assorted parts are not just numbers on a spreadsheet; they are the building blocks of success. With a comprehensive understanding of inventory assessment, management strategies, valuation methods, optimization techniques, replenishment strategies, control measures, forecasting methods, reporting systems, and audit procedures, the company ensures that every part is in its place, ready to contribute to the seamless flow of operations.

Questions and Answers

What is the significance of inventory assessment?

Inventory assessment provides a clear understanding of the composition and quantity of inventory, helping identify obsolete or duplicate parts and optimize stock levels.

How does inventory optimization benefit a company?

Inventory optimization reduces waste, minimizes carrying costs, and improves customer satisfaction by ensuring timely delivery of products.

What are the key elements of inventory control?

Inventory control involves cycle counting, perpetual inventory systems, and other techniques to prevent theft, loss, and damage, ensuring accurate inventory records.