A vendor managed inventory system refers to an – A vendor managed inventory (VMI) system empowers vendors to assume responsibility for managing their customers’ inventory levels, revolutionizing supply chain dynamics. This collaborative approach offers a myriad of benefits, from optimized inventory levels to reduced costs, making it an increasingly popular strategy among businesses.

A vendor managed inventory system refers to an automated process where a supplier takes responsibility for managing a customer’s inventory. Just like how 3 levels of managers in an organization work together to achieve goals, the vendor and customer collaborate to optimize inventory levels and ensure product availability.

This system enhances supply chain efficiency and reduces the risk of stockouts or excess inventory, leading to improved customer satisfaction and cost savings.

Delve into this comprehensive guide as we explore the intricacies of VMI systems, uncovering their advantages, potential challenges, and best practices. Discover how VMI can transform your supply chain, driving efficiency and profitability to new heights.

A vendor managed inventory system refers to an arrangement where a supplier takes responsibility for managing inventory levels at a customer’s location. This approach has gained popularity in healthcare, where a major hospital uses an agile approach to manage its inventory.

By partnering with a vendor, the hospital can improve efficiency, reduce costs, and ensure that critical supplies are always available.

Vendor Managed Inventory Systems

Vendor managed inventory (VMI) systems are a collaborative approach to inventory management where the vendor assumes responsibility for managing the inventory levels of the buyer.

A vendor managed inventory system refers to an arrangement where a supplier takes responsibility for managing the inventory of a customer. By leveraging 15 characteristics of an ideal performance management system , businesses can optimize inventory levels, reduce costs, and improve customer satisfaction.

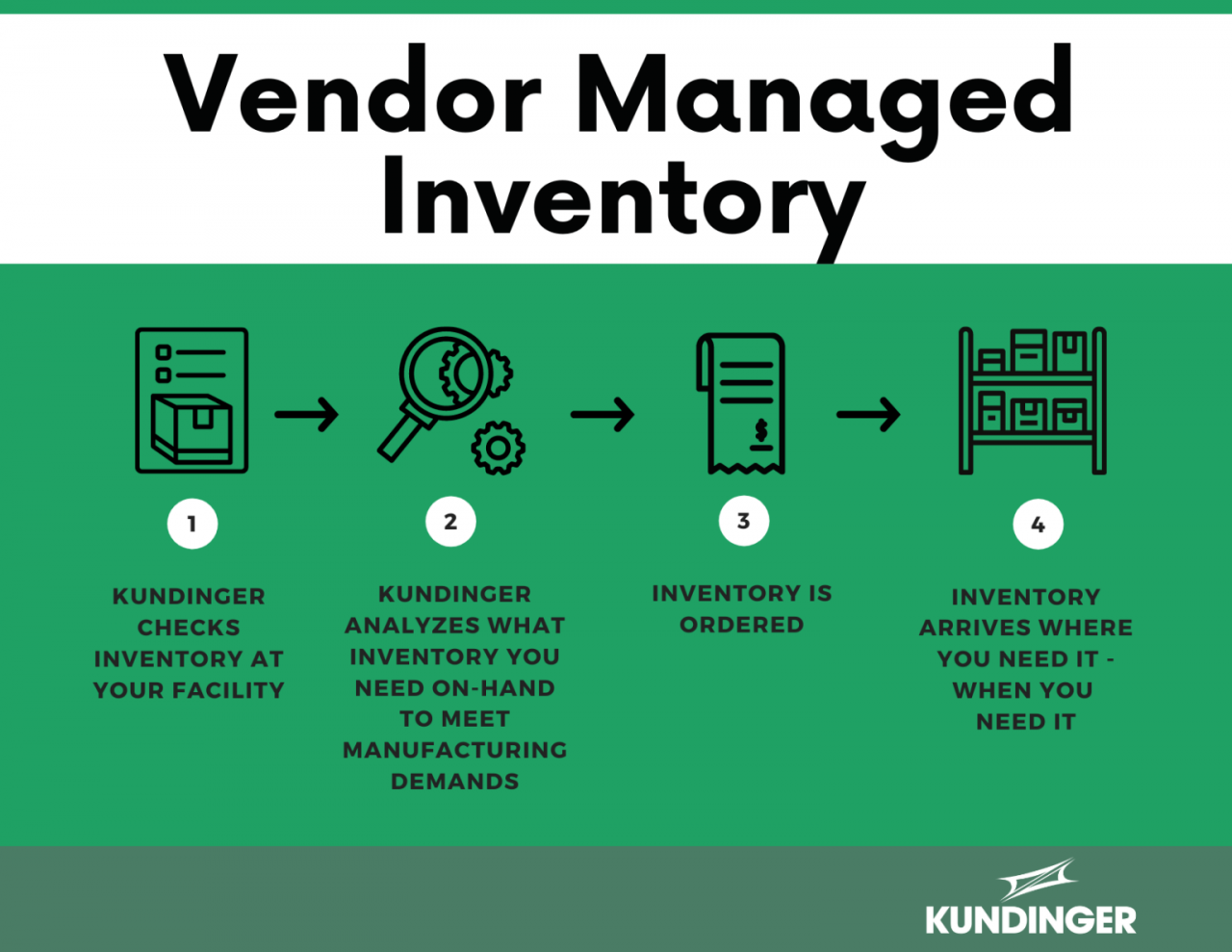

A vendor managed inventory system allows the supplier to monitor the customer’s inventory levels and automatically replenish stock when needed, ensuring that the customer always has the products they need.

Key characteristics and benefits of VMI systems include:

- Improved inventory accuracy and reduced stockouts

- Reduced inventory carrying costs

- Improved customer service levels

Benefits of Implementing a VMI System

VMI systems offer numerous benefits, including:

- Improved inventory management:VMI systems provide real-time visibility into inventory levels, allowing for more efficient inventory management and reduced stockouts.

- Cost reduction:VMI systems can help reduce inventory carrying costs by optimizing inventory levels and reducing waste.

- Improved customer service:VMI systems can help improve customer service levels by ensuring that products are always in stock and available to customers.

Challenges of Implementing a VMI System, A vendor managed inventory system refers to an

While VMI systems offer numerous benefits, there are also some challenges associated with implementing them, including:

- Trust and collaboration:VMI systems require a high level of trust and collaboration between vendors and buyers.

- Data sharing:VMI systems require the sharing of sensitive data between vendors and buyers, which can be a concern for some organizations.

- Complexity:VMI systems can be complex to implement and manage, especially for organizations with large or complex supply chains.

Types of VMI Systems

There are several different types of VMI systems, including:

- Consignment VMI:In a consignment VMI system, the vendor retains ownership of the inventory until it is sold by the buyer.

- Pull VMI:In a pull VMI system, the buyer initiates the replenishment process by placing an order with the vendor.

- Push VMI:In a push VMI system, the vendor manages the inventory levels of the buyer and replenishes inventory as needed.

Best Practices for Implementing a VMI System

To successfully implement a VMI system, it is important to follow best practices, including:

- Planning:Carefully plan the implementation of the VMI system, including defining roles and responsibilities, establishing performance metrics, and developing a communication plan.

- Communication:Establish clear and regular communication between the vendor and buyer throughout the implementation process.

- Performance monitoring:Monitor the performance of the VMI system regularly and make adjustments as needed.

Final Conclusion

In conclusion, VMI systems have emerged as a game-changer in supply chain management, enabling businesses to streamline inventory processes, minimize costs, and enhance customer satisfaction. As technology continues to advance, VMI systems will undoubtedly evolve, offering even greater opportunities for optimization.

By embracing VMI, businesses can position themselves for success in the ever-competitive global marketplace.

A vendor managed inventory system refers to an agreement between a retailer and a supplier where the supplier takes responsibility for managing the retailer’s inventory. This type of system can help to improve efficiency and reduce costs for both parties.

A specialized server that manages resources for an entire network can also help to improve efficiency and reduce costs for businesses. By centralizing the management of resources, businesses can gain a better understanding of their resource usage and can make more informed decisions about how to allocate those resources.

A vendor managed inventory system can help businesses to improve their inventory management and reduce their costs.

Detailed FAQs: A Vendor Managed Inventory System Refers To An

What are the key benefits of VMI systems?

A vendor managed inventory system refers to an inventory management technique where a supplier takes responsibility for maintaining a certain level of inventory for a customer. This system can be highly effective when managed by an effective manager. 10 characteristics of an effective manager include strong communication skills, the ability to delegate, and a focus on continuous improvement.

When these characteristics are applied to a vendor managed inventory system, the results can be significant.

VMI systems offer numerous benefits, including improved inventory accuracy, reduced inventory levels, lower storage costs, enhanced customer service, and streamlined supply chain processes.

What are the challenges associated with implementing VMI systems?

Implementing VMI systems requires careful planning and collaboration between vendors and buyers. Potential challenges include establishing clear communication channels, building trust, and ensuring data accuracy.

What are the different types of VMI systems?

There are several types of VMI systems, including consignment, pull, and push systems. Each type has its own advantages and disadvantages, and the best choice depends on the specific needs of the business.

A vendor managed inventory system refers to an arrangement where a vendor takes ownership of inventory management for a customer. To effectively manage this system, it’s crucial to have a project manager with exceptional qualities. As outlined in 10 qualities of an effective project manager , these individuals possess traits like strong leadership, communication skills, and the ability to adapt to changing circumstances.

By leveraging these qualities, project managers can ensure that vendor managed inventory systems operate seamlessly, delivering optimal outcomes for both vendors and customers.

A vendor managed inventory system refers to an approach where a supplier manages the inventory of a customer. This can be advantageous, as it can free up the customer’s time and resources to focus on other aspects of their business, such as s an advantage of managing a diverse workforce.

By leveraging the expertise of a supplier, businesses can optimize their inventory levels, reduce costs, and improve customer service. Ultimately, a vendor managed inventory system can streamline operations and enhance overall business performance.