A large company produces an equal number of products, a remarkable feat that requires meticulous planning, efficient resource allocation, and stringent quality control. This comprehensive guide delves into the strategies and challenges involved in maintaining equal production levels, exploring the intricacies of demand forecasting, inventory management, and continuous improvement.

Equal production is not merely a goal but a testament to a company’s operational excellence. By understanding the principles and best practices Artikeld in this guide, organizations can harness the power of equal production to optimize their operations, increase efficiency, and gain a competitive edge in the marketplace.

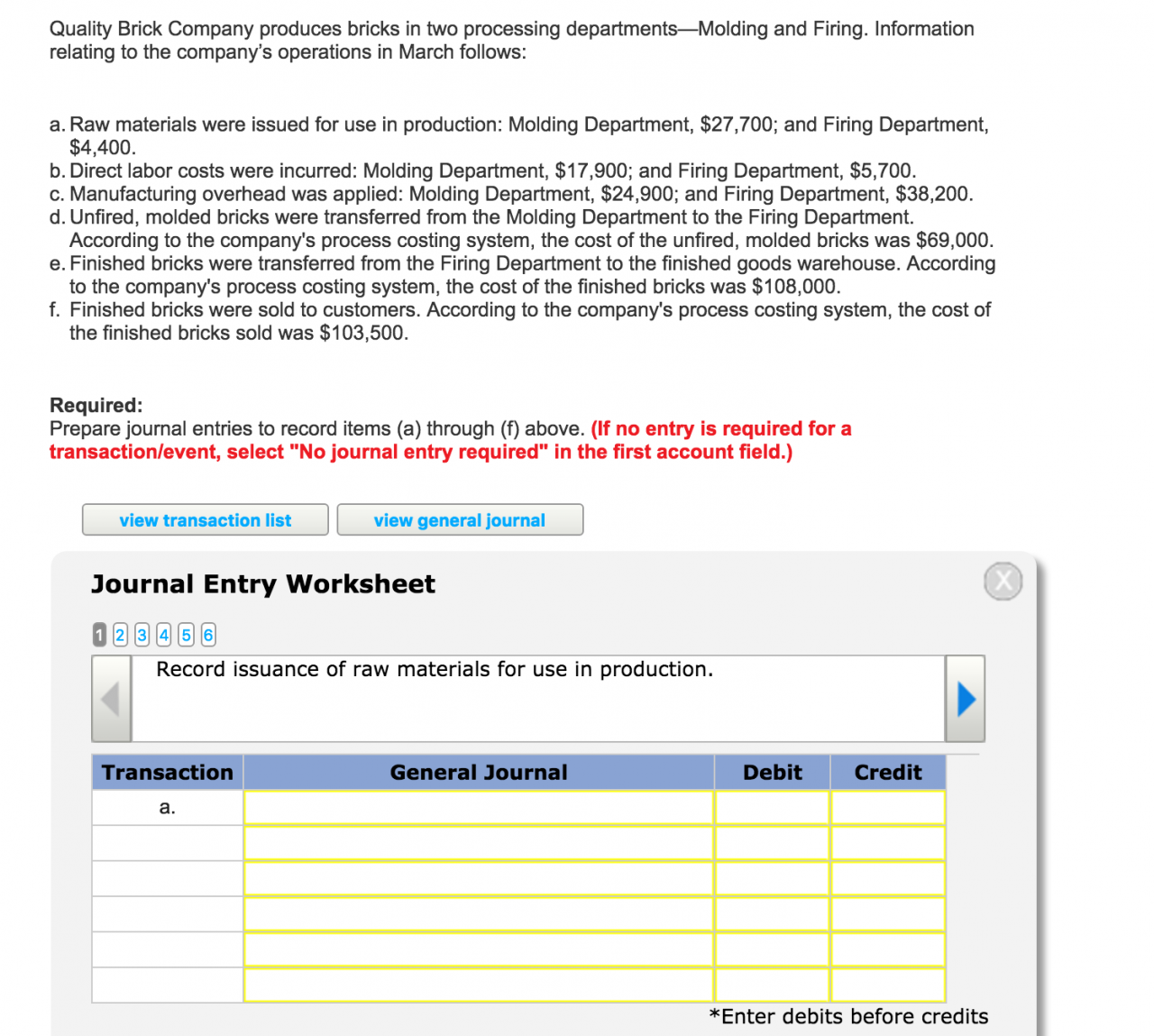

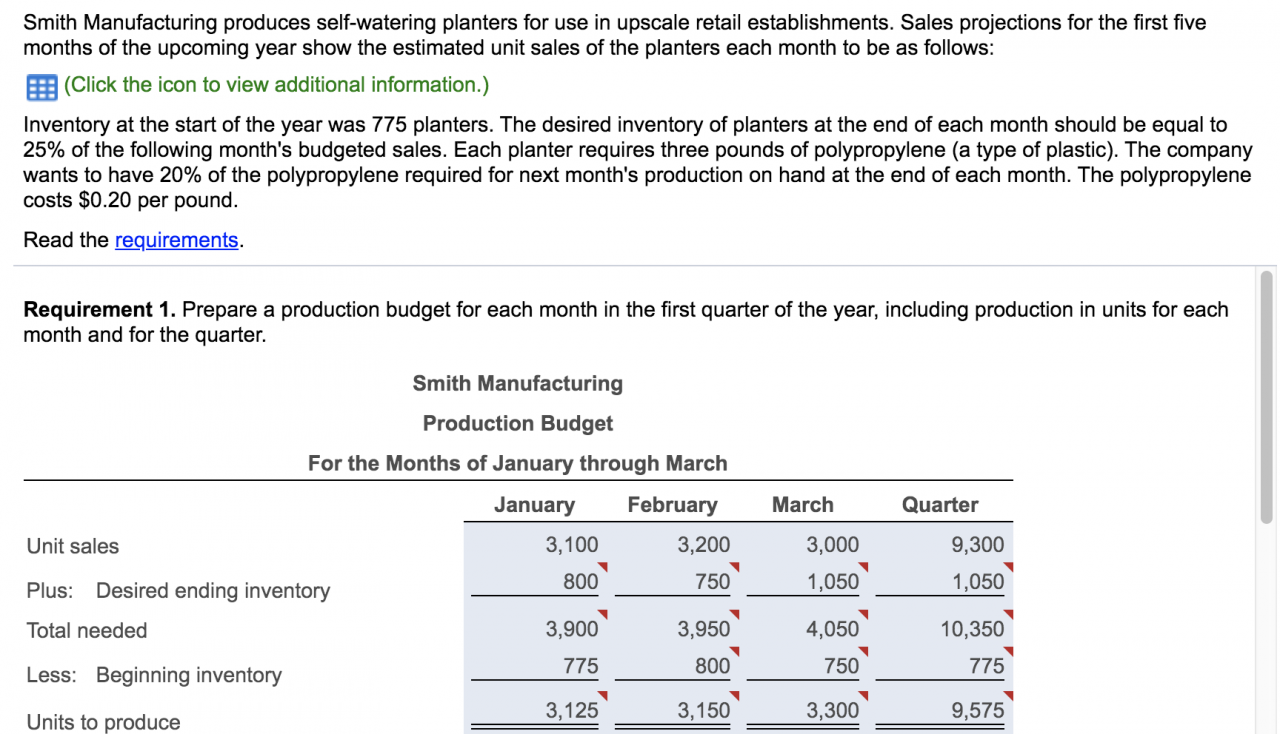

Production Quantities

This large company maintains an equal production output for various products, ensuring a consistent supply to meet market demand.

A large company produces an equal number of products that are compatible with both iOS and Android devices. However, can you access iCloud from an Android phone ? The answer is yes, but it’s not as straightforward as accessing iCloud from an Apple device.

A large company produces an equal number of products that are compatible with both iOS and Android devices.

Examples of products with equal production volumes include smartphones, laptops, and televisions. The company allocates resources to each product line to maintain a steady flow of production.

Reasons for Equal Production Levels

- Market demand:The company continuously monitors market demand to adjust production levels accordingly, ensuring that all products have sufficient supply to meet customer needs.

- Efficient resource allocation:By producing equal quantities of different products, the company optimizes resource allocation, avoiding imbalances and maximizing overall productivity.

- Streamlined operations:Equal production levels simplify manufacturing processes, allowing for efficient scheduling, inventory management, and distribution.

Resource Allocation

In order to produce an equal number of products, a company must carefully allocate its resources. This includes ensuring that the company has the right amount of raw materials, labor, and equipment to meet production demands. It also means that the company must allocate its resources in a way that ensures that each product is produced with the same level of quality.

There are a number of different resource allocation strategies that a company can use. One common strategy is to use a “push” system. In a push system, the company produces products based on its forecast of demand. This system can be efficient if the company’s forecast is accurate.

Did you know that a large company produces an equal number of popular mobile devices as their main competitor? If you’re curious about the features of the other company’s devices, you may wonder can i get siri on an android ? The answer to that question may surprise you.

After all, a large company produces an equal number of both iOS and Android devices.

However, if the forecast is inaccurate, the company may end up with too many or too few products.

A large company produces an equal number of iPhones and Androids, which has led to the question: can you access itunes from an android phone ? The answer is no, but there are workarounds. A large company produces an equal number of devices, so it’s important to know the differences between them.

Another common resource allocation strategy is to use a “pull” system. In a pull system, the company produces products only when there is a customer order. This system can be more efficient than a push system because it ensures that the company is only producing products that customers want.

However, a pull system can also be less efficient if there is a sudden increase in demand.

The best resource allocation strategy for a particular company will depend on a number of factors, including the type of products that the company produces, the demand for those products, and the company’s production capacity.

Challenges of Resource Allocation for Equal Production

There are a number of challenges that a company may face when allocating resources for equal production. One challenge is that the demand for different products may vary over time. This can make it difficult to ensure that the company has the right amount of resources to meet demand for all products.

A large company produces an equal number of Android and iOS devices, so it’s no surprise that people often wonder if they can track an iPhone from an Android phone. The answer is yes, and it’s actually quite easy to do.

Can I Track an iPhone from an Android Phone In fact, there are several different ways to do it. With a little bit of know-how, you can easily track an iPhone from an Android phone.

Another challenge is that the production process for different products may vary in terms of complexity and time required. This can make it difficult to ensure that all products are produced with the same level of quality.

Benefits of Resource Allocation for Equal Production

There are a number of benefits to resource allocation for equal production. One benefit is that it can help to improve the company’s efficiency. By ensuring that all products are produced with the same level of quality, the company can reduce the amount of waste and rework that is required.

Another benefit of resource allocation for equal production is that it can help to improve customer satisfaction. By ensuring that all products meet the same high standards of quality, the company can increase customer satisfaction and loyalty.

Production Capacity: A Large Company Produces An Equal Number Of

Production capacity is the maximum amount of output that a production system can produce over a given period of time. In order to maintain equal output, a company must have sufficient production capacity to meet the demand for its products.

There are a number of factors that can influence production capacity, including the following:

- The availability of raw materials

- The efficiency of the production process

- The number of workers available

- The amount of capital available

Methods to Adjust Production Capacity

There are a number of methods that can be used to adjust production capacity as needed. These methods include:

- Changing the number of workers

- Changing the amount of capital available

- Improving the efficiency of the production process

- Finding new sources of raw materials

Quality Control

To ensure equal production, a robust quality control system is implemented. The system encompasses meticulous inspection procedures at various stages of the production process, from raw material sourcing to finished product packaging.

Quality Standards Across Products

Maintaining consistent quality standards across diverse product lines is achieved through standardized operating procedures and rigorous testing protocols. These protocols ensure that each product meets the established specifications and customer expectations.

Challenges and Best Practices

Quality control for equal production presents unique challenges, such as managing variability in raw materials and maintaining consistency across different production lines. To overcome these challenges, best practices include:

- Rigorous supplier qualification and raw material testing

- Automated inspection systems and statistical process control

- Continuous training and certification of quality control personnel

- Regular audits and reviews of quality control processes

Demand Forecasting

Demand forecasting is crucial for equal production because it provides insights into future customer demand, enabling companies to align their production plans accordingly. Accurate demand forecasts help avoid overproduction or underproduction, ensuring optimal resource allocation and minimizing costs.

Various demand forecasting methods are employed to predict equal production requirements. These include historical data analysis, market research, surveys, and econometric models. Historical data analysis involves examining past demand patterns to identify trends and seasonality. Market research involves gathering data from customers and industry experts to understand their needs and preferences.

It’s like that big shot company that cranks out equal numbers of everything. Like, you know, that one that makes all the parts for your car engine ? Yeah, they’re like the ultimate assembly line masters, keeping that production line humming with an equal number of every single piece.

Surveys can be conducted to collect specific information about customer demand for a particular product or service.

Incorporation of Demand Forecasts into Production Planning

Demand forecasts are incorporated into production planning through a process called aggregate planning. Aggregate planning involves determining the overall production levels and resource allocation for a given period, typically a month or quarter. Demand forecasts are used to estimate the total demand for a product or service during the planning period.

This information is then used to determine the production capacity required to meet the demand, as well as the allocation of resources such as labor, materials, and equipment.

Importance of Accurate Demand Forecasting for Equal Production

Accurate demand forecasting is critical for equal production because it helps companies avoid the following issues:

- Overproduction: When demand forecasts are inaccurate, companies may produce more than the actual demand, leading to excess inventory and increased costs.

- Underproduction: Inaccurate demand forecasts can also lead to underproduction, resulting in lost sales, customer dissatisfaction, and reputational damage.

- Inefficient resource allocation: Inaccurate demand forecasts can lead to inefficient resource allocation, such as overstaffing or understaffing, which can increase costs and reduce productivity.

By utilizing accurate demand forecasting methods and incorporating them into production planning, companies can ensure equal production, optimize resource allocation, and minimize costs.

Inventory Management

For equal production, inventory management strategies focus on maintaining a consistent flow of raw materials, components, and finished goods to support uninterrupted production schedules. Inventory levels are optimized to ensure availability while minimizing waste and storage costs.

Challenges, A large company produces an equal number of

- Balancing supply and demand: Ensuring adequate inventory levels to meet production requirements without overstocking.

- Minimizing waste: Preventing spoilage, obsolescence, or damage of inventory.

- Optimizing storage space: Efficiently utilizing available storage space to minimize costs and maintain inventory accessibility.

Benefits

- Ensured production continuity: Adequate inventory levels support uninterrupted production schedules.

- Reduced lead times: Optimized inventory levels minimize the time required to obtain necessary materials or components.

- Improved customer service: Availability of inventory enables prompt fulfillment of orders.

Scheduling and Planning

Scheduling and planning are crucial processes in achieving equal production, ensuring that resources are allocated efficiently and production runs smoothly. Coordination and synchronization are key to successful scheduling, as they prevent bottlenecks and delays.

Challenges of Scheduling and Planning

- Resource constraints:Limited availability of equipment, materials, and labor can hinder production.

- Demand fluctuations:Unpredictable changes in demand can disrupt production schedules.

- Machine downtime:Equipment breakdowns or maintenance can cause delays and affect production capacity.

Best Practices for Scheduling and Planning

- Capacity planning:Determine the maximum production capacity and plan accordingly.

- Master production schedule:Create a comprehensive schedule that Artikels production targets and timelines.

- Just-in-time (JIT) production:Minimize inventory and produce only what is needed, when it is needed.

- Communication and coordination:Establish clear communication channels between departments to ensure smooth production flow.

Employee Training and Development

A comprehensive training and development program is crucial for maintaining equal production levels and ensuring employee proficiency in their respective roles. Employees undergo rigorous training to develop the necessary skills, knowledge, and techniques to meet production targets consistently.

Big companies may manufacture a uniform amount of items, but that doesn’t mean they all perform the same. Take FaceTime, for example: while it’s a popular video calling app on iPhones, can facetime be installed on an android phone ? The answer may surprise you!

Training Programs

- On-the-job training:Employees receive hands-on experience under the guidance of experienced supervisors, allowing them to learn the production process firsthand.

- Classroom training:Theoretical knowledge and industry best practices are imparted through structured classroom sessions, covering topics such as production techniques, quality control, and safety protocols.

- Computer-based training:Interactive software simulations provide employees with a safe and controlled environment to practice production procedures and troubleshoot potential issues.

Maintaining Consistent Production Levels

To ensure consistent production levels, employees receive ongoing training and support. Refresher courses and workshops reinforce key concepts and update employees on the latest advancements in production methods. Additionally, performance evaluations and feedback mechanisms allow supervisors to identify areas for improvement and provide targeted training interventions.

A large company produces an equal number of Android and iOS devices. If you’re an Android user, you might be wondering if you can access iCloud from your device. The answer is yes! With a few simple steps, you can access your iCloud account from your Android phone or tablet.

Can you access iCloud from an Android ? Yes, you can! iCloud is a cloud storage and computing service from Apple. It allows you to store your photos, videos, documents, and other files online. You can access your iCloud account from any device with an internet connection.

A large company produces an equal number of Android and iOS devices.

Challenges and Benefits

Challenges

- Time and resource constraints:Providing comprehensive training can be time-consuming and require significant resources, which can strain operational efficiency.

- Employee turnover:Training investments can be lost if employees leave the organization before reaching full proficiency.

- Adapting to technological advancements:As production technologies evolve, training programs must be regularly updated to ensure employees stay abreast of the latest innovations.

Benefits

- Improved productivity:Well-trained employees possess the skills and knowledge to perform their tasks efficiently, leading to increased production output.

- Reduced errors and waste:Training helps employees understand the importance of quality control and minimizes the occurrence of errors, reducing waste and rework.

- Enhanced job satisfaction:Employees who receive training feel valued and motivated, leading to increased job satisfaction and retention.

Continuous Improvement

Continuous improvement is a systematic and ongoing process of evaluating and improving production processes to increase efficiency and quality. In the context of equal production, continuous improvement initiatives focus on ensuring that all products are manufactured to the same high standards, regardless of their origin or production line.

Production Process Evaluation

Continuous improvement initiatives begin with a thorough evaluation of existing production processes. This involves identifying areas for improvement, such as bottlenecks, inefficiencies, and quality issues. Once these areas have been identified, a plan can be developed to address them.

Technology and Innovation

Technology and innovation play a crucial role in continuous improvement for equal production. New technologies can be used to automate tasks, improve quality control, and increase production efficiency. For example, automated optical inspection (AOI) systems can be used to identify defects in products, while statistical process control (SPC) software can be used to monitor production processes and identify areas for improvement.

Employee Training and Development

Employee training and development are also essential for continuous improvement. Employees need to be trained on new technologies and processes, and they need to be given the opportunity to provide feedback on how production processes can be improved.

Results and Benefits

Continuous improvement initiatives can lead to a number of benefits, including:

- Increased production efficiency

- Improved product quality

- Reduced costs

- Increased customer satisfaction

Final Thoughts

In conclusion, a large company produces an equal number of products through a combination of strategic planning, resource optimization, and continuous improvement. By embracing the principles Artikeld in this guide, organizations can unlock the full potential of equal production, driving operational excellence and achieving long-term success.

Detailed FAQs

What are the benefits of equal production?

Equal production offers numerous benefits, including optimized resource allocation, reduced waste, improved quality control, and increased efficiency.

How does a company ensure equal production of different products?

Equal production is achieved through a combination of demand forecasting, production planning, resource allocation, quality control, and inventory management.

What are the challenges of maintaining equal production?

Challenges include fluctuating demand, resource constraints, quality variations, and the need for continuous improvement.