System Overview

Designing an inventory management system – An inventory management system (IMS) is a software application that helps businesses track and manage their inventory. It can be used to manage inventory levels, track inventory movements, and generate reports on inventory data. IMSs can be used by businesses of all sizes, and they can be customized to meet the specific needs of each business.

Designing an inventory management system involves understanding the financial implications of inventory levels and turnover rates. For a comprehensive overview of multinational financial management, refer to chapter 1 multinational financial management an overview. This resource provides insights into the impact of inventory management on cash flow, profitability, and risk exposure.

By integrating financial principles into inventory management, businesses can optimize their operations and enhance their financial performance.

There are many benefits to using an IMS. Some of the benefits include:

- Improved inventory accuracy

- Reduced inventory costs

- Increased customer satisfaction

- Improved operational efficiency

IMSs can be used in a variety of industries, including:

- Retail

- Manufacturing

- Distribution

- Healthcare

- Government

There are different types of IMSs available. Some of the most common types include:

- Perpetual inventory systems

- Periodic inventory systems

- Just-in-time inventory systems

- Vendor-managed inventory systems

Key Components

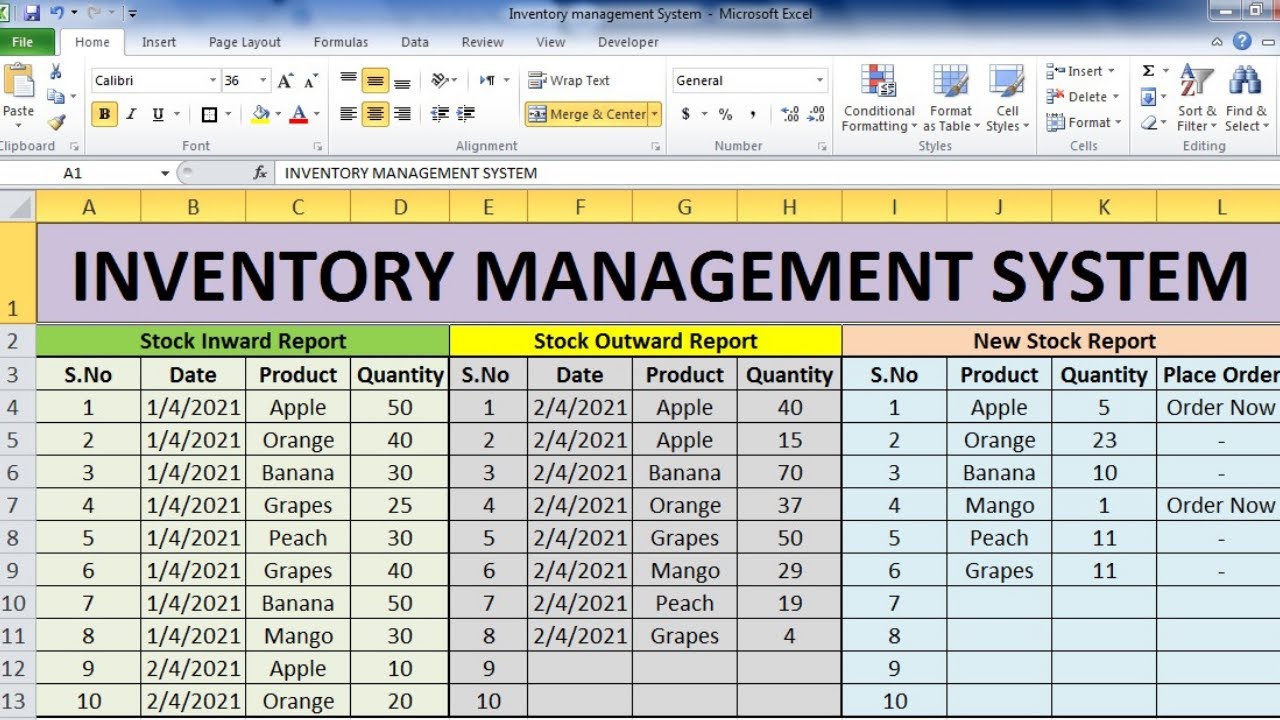

The key components of an IMS include:

- Inventory database

- Inventory tracking system

- Inventory reporting system

The inventory database stores information about each item in inventory, including the item’s name, description, quantity, and location. The inventory tracking system tracks the movement of inventory items, including when items are received, shipped, or sold. The inventory reporting system generates reports on inventory data, such as inventory levels, inventory turnover, and inventory costs.

To design an efficient inventory management system, businesses must consider various factors, such as demand forecasting and warehouse management. Additionally, integrating advertising campaigns is crucial for driving sales. To effectively manage your Facebook advertising, it’s essential to create an ad account in Facebook Business Manager.

This step allows you to control your ad spending, track campaign performance, and optimize your targeting strategies. By integrating these elements into your inventory management system, businesses can enhance their overall efficiency and profitability.

These components work together to manage inventory effectively. The inventory database provides the data that the inventory tracking system uses to track the movement of inventory items. The inventory reporting system uses the data from the inventory tracking system to generate reports on inventory data.

Designing an inventory management system requires a deep understanding of business management skills. These skills, such as those outlined in this article , are essential for understanding how inventory levels affect cash flow, customer satisfaction, and overall profitability. By implementing these skills, entrepreneurs can create an inventory management system that optimizes stock levels, minimizes waste, and maximizes efficiency.

Data Management, Designing an inventory management system

Accurate and up-to-date inventory data is essential for effective inventory management. IMSs use a variety of methods to collect, store, and maintain inventory data. Some of the most common methods include:

- Barcode scanning

- RFID tags

- Manual data entry

Once inventory data has been collected, it is stored in an inventory database. The inventory database is a central repository for all inventory data. It contains information about each item in inventory, including the item’s name, description, quantity, and location.

As we embark on the meticulous process of designing an inventory management system, it is imperative to recognize the profound artistry inherent in management. Just as defining management as an art highlights its delicate balance of science and intuition, so too does crafting an efficient inventory system require a keen eye for detail and an understanding of both quantitative and qualitative factors.

Inventory data must be maintained on a regular basis to ensure that it is accurate and up-to-date. This can be done by using a variety of methods, such as:

- Physical inventory counts

- Cycle counting

- Data validation

By using these methods, businesses can ensure that their inventory data is accurate and up-to-date.

Designing an inventory management system requires careful consideration of factors such as demand forecasting, stock levels, and order fulfillment. As Cary, the marketing manager for an automobile dealership , understands, managing inventory efficiently is crucial for optimizing sales and customer satisfaction.

An effective inventory management system can help businesses minimize waste, reduce costs, and improve overall operational efficiency.

Inventory Control

Inventory control is the process of managing inventory levels to meet customer demand while minimizing inventory costs. IMSs use a variety of techniques to control inventory levels, including:

- Safety stock

- Reorder points

- Inventory forecasting

Safety stock is a buffer of inventory that is kept on hand to protect against unexpected changes in demand or supply. Reorder points are the levels at which inventory should be reordered. Inventory forecasting is the process of predicting future demand for inventory items.

Designing an inventory management system involves collecting and organizing data to track and manage inventory levels. This data, which is part of the collection of information used to support management of an organization , includes product descriptions, quantities, locations, and reorder points.

By analyzing this data, businesses can optimize inventory levels, reduce costs, and improve customer service.

By using these techniques, businesses can control their inventory levels effectively. They can ensure that they have enough inventory on hand to meet customer demand, while minimizing inventory costs.

Final Conclusion

By following the tips in this article, you can design an inventory management system that will help you improve your efficiency and accuracy. With a well-designed system, you can reduce your costs, improve your customer service, and gain a competitive advantage.

Expert Answers: Designing An Inventory Management System

What are the benefits of using an inventory management system?

An inventory management system can provide a number of benefits, including:

- Reduced stockouts

- Reduced overstocking

- Optimized ordering process

- Improved customer service

- Reduced costs

What are the key components of an inventory management system?

The key components of an inventory management system include:

- A database to store inventory data

- A user interface to access and update inventory data

- A reporting module to generate reports on inventory levels, orders, and other data

- An integration module to connect the inventory management system to other business systems, such as ERP and accounting software

How do I choose the right inventory management system for my business?

There are a number of factors to consider when choosing an inventory management system, including:

- The size of your business

- The type of inventory you manage

- Your budget

- Your technical expertise

When designing an inventory management system, it is essential to consider the principles of evidence-based human resource management. As evidence-based human resource management suggests, data and research should guide decisions to optimize employee performance and satisfaction. Similarly, in designing an inventory management system, data analysis and research can help determine optimal inventory levels, reorder points, and safety stock levels, ensuring efficient and cost-effective inventory management.

Designing an inventory management system requires understanding customer needs and preferences. Customer experience management plays a crucial role in this, as it provides insights into customer behavior and expectations. By integrating customer experience data into inventory management, businesses can optimize stock levels, improve product availability, and enhance customer satisfaction.