Inventory Management System Design

Develop an inventory management system – Inventory management systems (IMS) are designed to optimize the flow of goods within a business. By tracking inventory levels, automating processes, and providing real-time data, IMSs can help businesses reduce costs, improve efficiency, and increase customer satisfaction.

Developing an inventory management system involves tracking and managing physical assets, which can align with the components of an environmental management system, such as inventory management. This integration allows organizations to monitor the environmental impact of their inventory, ensuring compliance with regulations and reducing waste.

Benefits of Implementing an IMS

- Reduced inventory costs: IMSs help businesses identify and eliminate excess inventory, reducing storage and carrying costs.

- Improved customer service: IMSs provide real-time inventory data, enabling businesses to fulfill orders more quickly and accurately.

- Increased efficiency: IMSs automate inventory management tasks, freeing up employees to focus on other value-added activities.

Examples of Industries that Benefit from an IMS

- Manufacturing: IMSs help manufacturers track raw materials, work-in-progress, and finished goods, ensuring optimal production levels.

- Retail: IMSs help retailers manage inventory levels across multiple locations, reduce stockouts, and improve customer satisfaction.

- Healthcare: IMSs help hospitals and clinics track medical supplies, ensuring patient safety and reducing waste.

Key Components of an IMS

- Inventory tracking: IMSs use barcodes, RFID tags, or other technologies to track inventory levels in real time.

- Inventory management: IMSs provide tools for managing inventory levels, including setting reorder points, issuing purchase orders, and adjusting stock levels.

- Inventory optimization: IMSs use algorithms to optimize inventory levels, reducing excess inventory and ensuring product availability.

Inventory Tracking and Management

Inventory tracking and management are essential components of inventory management. Effective inventory tracking provides real-time visibility into inventory levels, while inventory management ensures that inventory is optimized to meet customer demand.

To establish an efficient inventory management system, managers must possess key characteristics such as decisiveness, strategic thinking , and adaptability. These qualities empower them to optimize inventory levels, minimize costs, and respond swiftly to market fluctuations, ensuring a seamless and cost-effective supply chain operation.

Methods for Tracking Inventory Levels

- Manual counting: This involves physically counting inventory items on a regular basis.

- Barcode scanning: Barcodes can be used to track inventory items as they are received, stored, and shipped.

- RFID tracking: RFID tags can be attached to inventory items to track their location and movement.

Procedures for Managing Inventory Levels

- Setting reorder points: Reorder points are the inventory levels at which a new order should be placed.

- Issuing purchase orders: Purchase orders are used to order inventory from suppliers.

- Adjusting stock levels: Stock levels should be adjusted as inventory is received, sold, or damaged.

Best Practices for Inventory Optimization

- Use a demand forecasting tool to predict future demand.

- Set safety stock levels to buffer against unexpected fluctuations in demand.

- Conduct regular inventory audits to ensure accuracy.

Inventory Control and Forecasting: Develop An Inventory Management System

Inventory control and forecasting are critical for managing inventory levels effectively. Inventory control ensures that inventory is protected from theft, damage, and obsolescence, while inventory forecasting helps businesses predict future demand.

Developing an inventory management system is a crucial aspect of modern business operations, requiring a deep understanding of the principles of management. As defined by management as an art , it involves the effective coordination and allocation of resources to achieve desired outcomes.

An inventory management system enables businesses to optimize stock levels, reduce waste, and improve supply chain efficiency, ultimately contributing to increased profitability and customer satisfaction.

Techniques for Inventory Control, Develop an inventory management system

- Physical security measures: This includes measures such as locks, fences, and security cameras.

- Inventory audits: Regular inventory audits help identify and correct any discrepancies in inventory levels.

- First-in, first-out (FIFO) and last-in, first-out (LIFO) methods: These methods are used to determine the cost of goods sold.

Methods for Forecasting Inventory Demand

- Historical data analysis: This involves analyzing past sales data to identify trends and patterns.

- Market research: This involves gathering data on market conditions, customer preferences, and competitor activity.

- Econometric models: These models use statistical techniques to forecast demand based on economic indicators.

Examples of Inventory Control and Forecasting Tools

- Inventory management software: This software can help businesses track inventory levels, manage purchase orders, and forecast demand.

- Demand forecasting tools: These tools can help businesses predict future demand based on historical data, market research, and econometric models.

- Inventory optimization tools: These tools can help businesses optimize inventory levels to minimize costs and improve customer service.

Inventory Replenishment and Procurement

Inventory replenishment and procurement are important aspects of inventory management. Inventory replenishment involves the process of ordering and receiving inventory, while inventory procurement involves the process of selecting and acquiring inventory from suppliers.

Developing an inventory management system requires meticulous planning and project management skills. Training individuals to become project managers can ensure successful implementation of inventory systems, as they possess the expertise to coordinate tasks, manage resources, and deliver projects on time and within budget.

Strategies for Inventory Replenishment

- Just-in-time (JIT) inventory: This strategy involves ordering inventory only when it is needed, reducing inventory carrying costs.

- Periodic inventory replenishment: This strategy involves ordering inventory at regular intervals, regardless of demand.

- Kanban inventory replenishment: This strategy uses visual signals to trigger the replenishment of inventory.

Methods for Inventory Procurement

- Supplier selection: This involves evaluating and selecting suppliers based on factors such as price, quality, and reliability.

- Negotiating contracts: This involves negotiating terms such as price, delivery time, and payment terms.

- Managing supplier relationships: This involves building and maintaining strong relationships with suppliers.

Tips for Optimizing Inventory Replenishment and Procurement

- Use a vendor management system (VMS) to manage supplier relationships.

- Implement a procurement card program to streamline the purchasing process.

- Use electronic data interchange (EDI) to automate the exchange of purchase orders and invoices.

Inventory Reporting and Analysis

Inventory reporting and analysis are essential for monitoring inventory performance and making informed decisions. Inventory reporting provides data on inventory levels, costs, and turnover, while inventory analysis helps businesses identify trends and patterns.

Developing an inventory management system is essential for businesses to manage their stock effectively. This system can help organizations to identify potential crises, such as shortages or surpluses, and develop contingency plans to mitigate their impact. By integrating crisis management strategies into inventory management systems, businesses can ensure that they are prepared to respond to unexpected events and minimize disruptions to their operations.

This can help organizations to maintain a competitive advantage and protect their reputation in the face of adversity.

Types of Inventory Reports

- Inventory valuation report: This report shows the value of inventory on hand at a specific point in time.

- Inventory turnover report: This report shows how quickly inventory is being sold.

- Inventory aging report: This report shows the age of inventory on hand.

Methods for Inventory Analysis

- Trend analysis: This involves analyzing inventory data over time to identify trends and patterns.

- Ratio analysis: This involves calculating ratios such as inventory turnover and inventory days on hand to assess inventory performance.

- Variance analysis: This involves comparing actual inventory levels to budgeted levels to identify variances.

Examples of Inventory Reporting and Analysis Tools

- Inventory management software: This software can generate a variety of inventory reports and analysis tools.

- Spreadsheets: Spreadsheets can be used to create custom inventory reports and analysis tools.

- Data visualization tools: These tools can be used to visualize inventory data and identify trends and patterns.

Final Review

In conclusion, developing an inventory management system is a strategic investment that empowers businesses to gain control over their inventory operations. By embracing the principles Artikeld in this guide, organizations can streamline their inventory processes, optimize their inventory levels, and ultimately drive business growth and profitability.

FAQ Resource

What are the key benefits of implementing an inventory management system?

Developing an inventory management system is crucial for businesses to optimize stock levels, reduce costs, and enhance customer satisfaction. By implementing such a system, companies can gain real-time visibility into their inventory, enabling them to make informed decisions and improve their overall supply chain efficiency.

Moreover, this system can be integrated with customer relationship management (CRM) tools to enhance customer experience management , leading to increased customer loyalty and repeat purchases.

An inventory management system provides numerous benefits, including improved inventory accuracy, reduced carrying costs, enhanced customer service, optimized inventory levels, and increased profitability.

What industries can benefit from an inventory management system?

Inventory management systems are beneficial for a wide range of industries, including retail, manufacturing, healthcare, hospitality, and distribution.

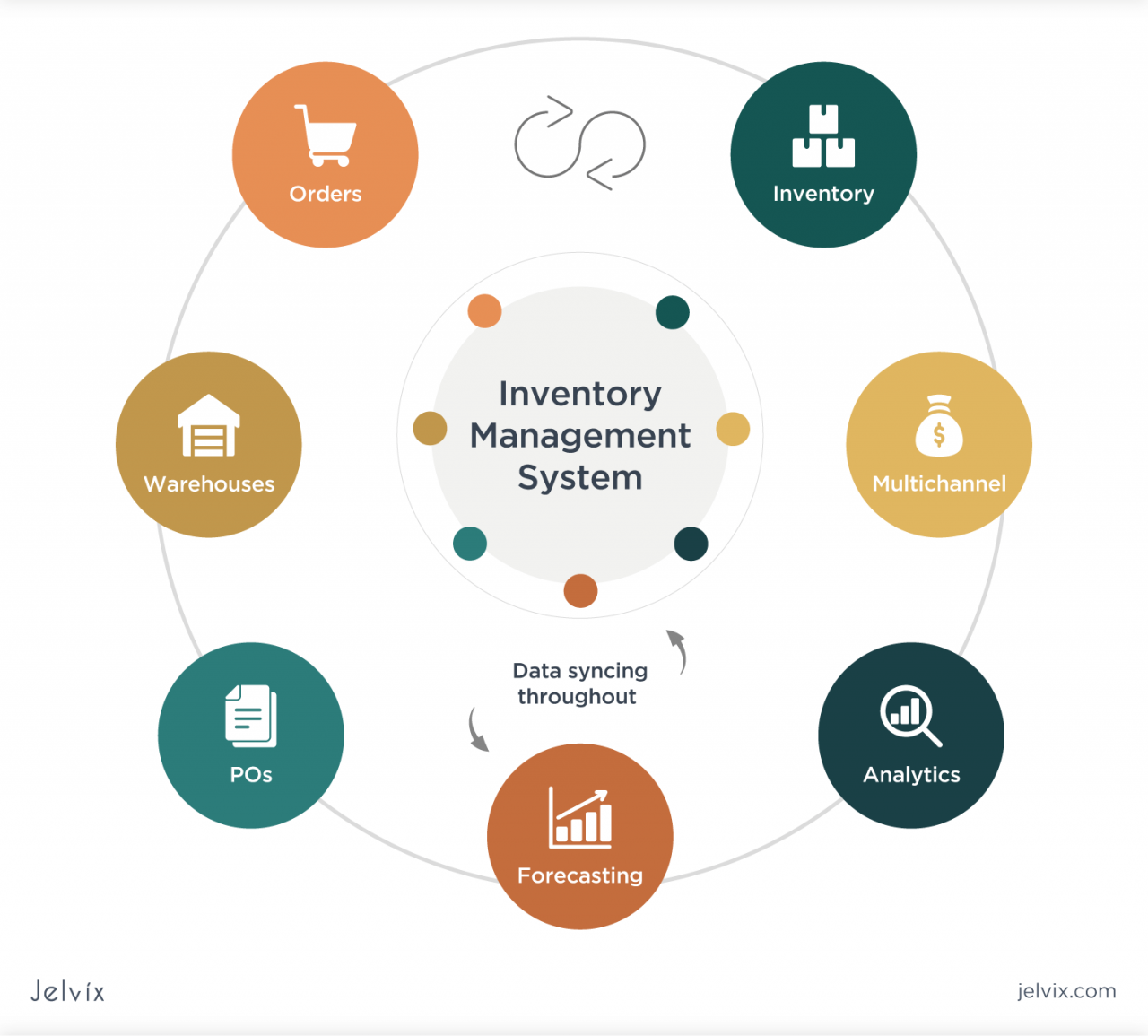

What are the essential components of an inventory management system?

The key components of an inventory management system include inventory tracking, inventory control, inventory forecasting, inventory replenishment, and inventory reporting.

Developing an inventory management system requires a comprehensive approach that encompasses project management principles. In his seminal work, Carl Scott’s Information Technology Project Management: An Integrated Approach , he outlines a structured framework for managing IT projects, including inventory management systems.

By integrating these principles into the development process, organizations can ensure the efficient implementation and ongoing optimization of their inventory management solutions.

Developing an inventory management system is crucial for organizations facing challenges of management. By streamlining inventory processes, organizations can improve efficiency, reduce costs, and enhance customer satisfaction. An effective inventory management system provides real-time visibility into stock levels, optimizes ordering and replenishment, and minimizes waste.